About Us

Environmental Protection and Regeneration System Solution Comprehensive Service Provider

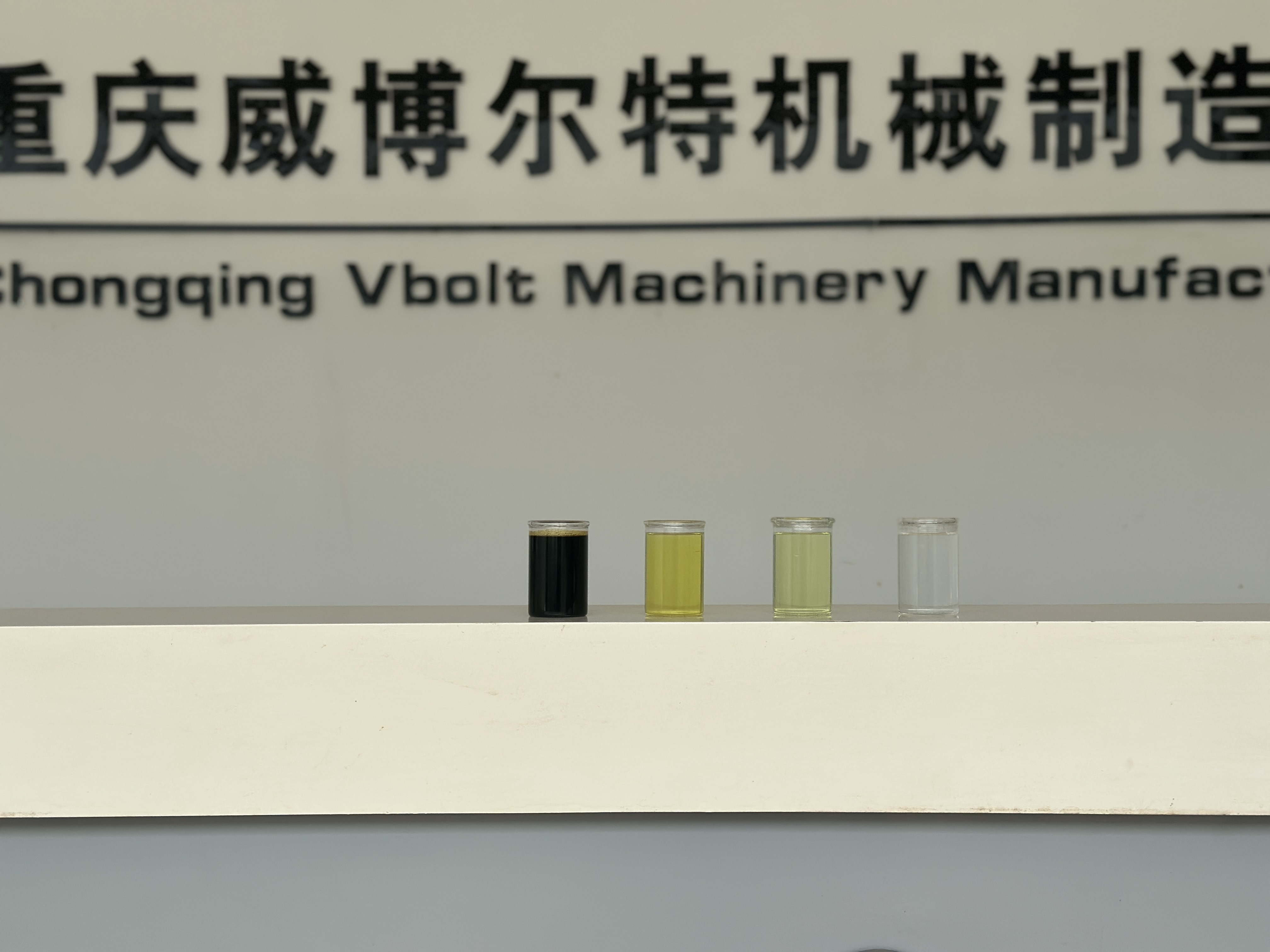

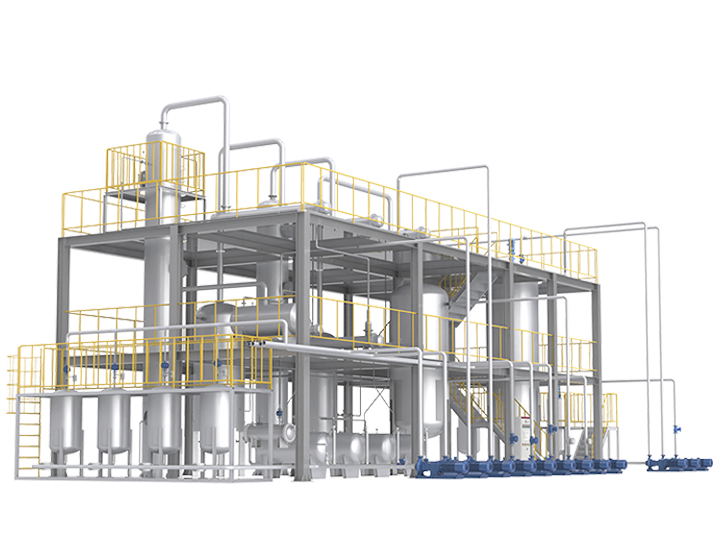

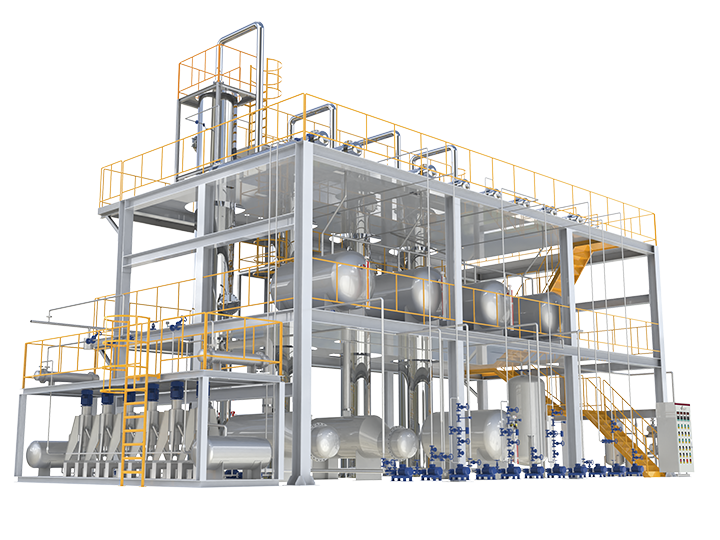

VBOLT has formed a complete technical closed loop covering pretreatment - regeneration - refining - application in the field of waste oil regeneration and lubricating oil treatment. Its core product system includes: complete sets of equipment for waste oil regeneration diesel, waste oil regeneration base oil distillation system, lubricating oil solvent extraction device and intelligent lubricating oil blending equipment, aiming to provide global customers with full industrial chain technical solutions.

Since

Factory Area

Technical Patents

Engineering Solutions

Petrochemical

Engineering Solutions

Transportation

Engineering Solutions

Power industry

Engineering Solutions

Engineering machinery

— Our Advantages —

Reasons to Choose Us

We serve every customer with sincerity, value every question, pay attention to every detail, and provide customers with satisfactory and high-quality services.

Strong Strength

◎ Our company has a strong technical research and development system and a complete technical development process;

◎ Under the incentive of the company's modern management mechanism, nearly twenty series of products and hundreds of models have been successfully developed;

◎ We can also customize various products according to customer needs.

Standard Production

◎ Production processes are strictly implemented in accordance with standardized standards;

◎ In accordance with the Ministry of Mechanical Industry JB/T5285-2008 standard;

◎ Ministry of Electric Power DL/T521-2004 standard production;

◎ Advanced production equipment;

Intimate Service

◎ Senior experienced engineers provide professional technical guidance;

◎ Solve the problems you encounter in the production process;

◎ 24-hour telephone response;

◎ Professional customer service is always available;

— Our Services —

Provide customers with satisfactory and high-quality services

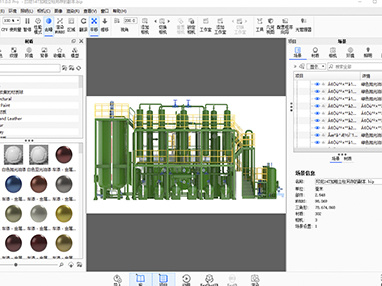

3D Drawings

Engineers build three-dimensional engineering drawings based on customer technical parameters to support practice with theory.

Production and Manufacturing

Based on drawings and professional theories, efficient workshop manufacturing is realized.

Delivery Guidance

After the equipment is delivered, our engineers will go to the site to provide installation guidance services.

After-sales Service

Establish a complete customer data file, provide lifelong service for the sold equipment, and provide various spare parts and consumables to solve the worries for users.

— Latest Blog

Learn about our latest news

2024-11-06

2024-11-06

What is the working principle of a vacuum oil filter?

2024-11-06

Application of fiber ball filter in oilfield wastewater treatment

2024-11-06

How to use a backwashing filter? Remember these points, and operation will not be a worry