Base oil solvent extraction equipment

Base oil extraction equipment primarily utilizes the difference in solubility of different substances in specific solvents to achieve the separation and extraction of base oil. Its working principle is as follows:

1. Solvent Selection

Select a specific solvent that has high solubility for the target components in the base oil, but low solubility for impurities. Common solvents include propane and furfural.

2. Mixing and Dissolution

Thoroughly mix the raw materials, such as waste lubricating oil, with the solvent. Under certain temperature and pressure conditions, the ideal components in the base oil dissolve in the solvent, while impurities such as resins and asphaltenes are insoluble or have very low solubility.

3. Separation Stage

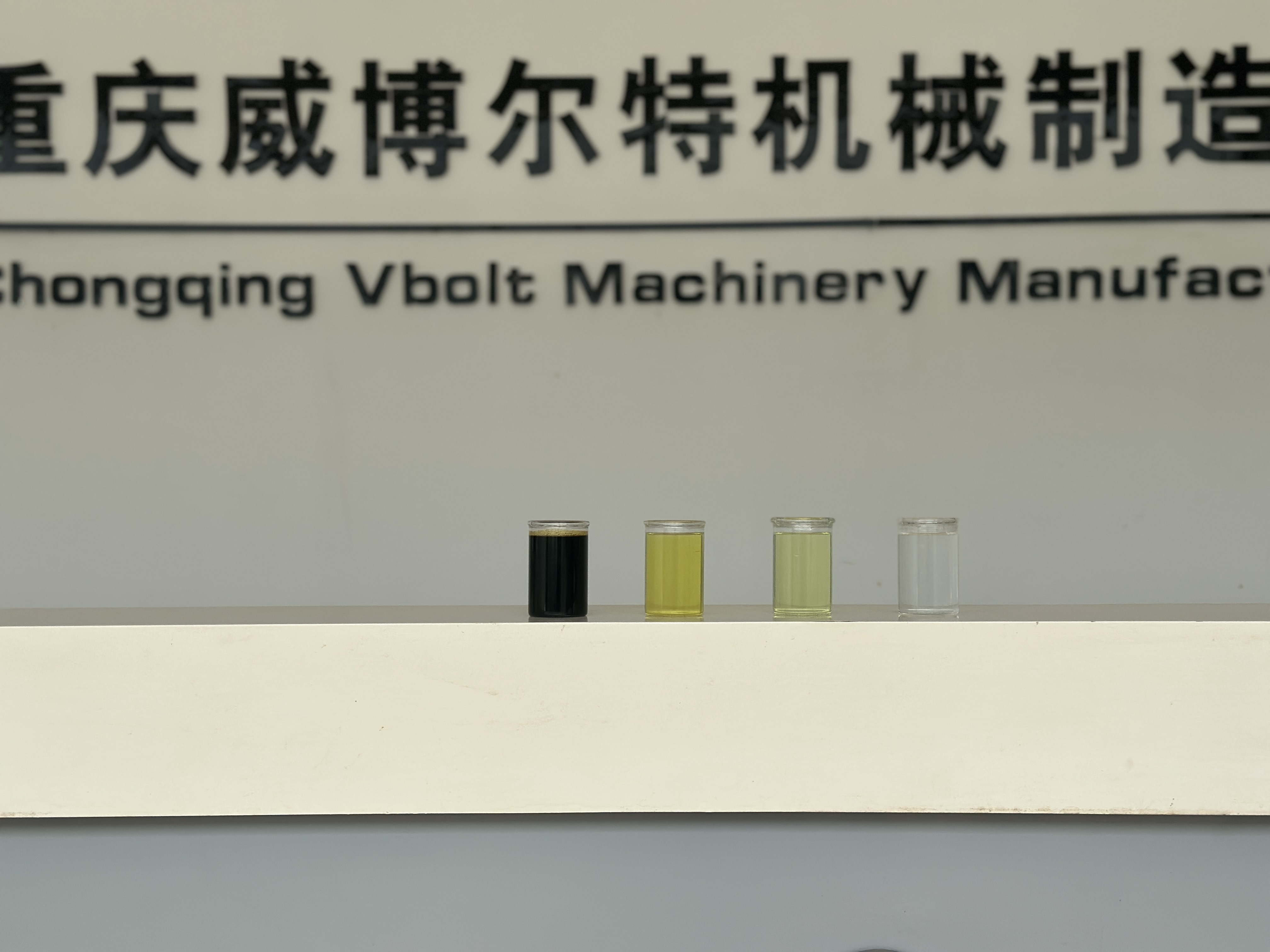

Use physical methods such as sedimentation and centrifugation to separate the solvent phase containing the base oil components from the insoluble impurity phase.

Alternatively, use specific equipment such as an extraction column to achieve continuous phase separation. The heavier impurity phase sinks, and the lighter solvent and base oil mixture rises.

4. Solvent Recovery

Treat the solvent phase containing the base oil by changing the temperature and pressure to evaporate or volatilize the solvent, thereby separating the base oil. The recovered solvent can be recycled to reduce costs.

Application Areas

Concept and Overview

Technical services

- PRODUCT

Application Areas

1. Industrial Machinery Used for gear oil, hydraulic oil, compressor oil, etc., to reduce equipment friction and wear.

2. Automotive Industry Formulating engine oil, transmission oil, brake fluid, etc., to ensure efficient vehicle operation.

3. Marine and Aviation As a base component for turbine oil and lubricating grease, suitable for extreme conditions.

4. Cutting Fluid/Rolling Fluid Cooling and lubricating during processing, improving surface finish.

5. Rust Preventive Oil Protects metal parts from corrosion and extends storage life.

- PRODUCT

Concept and Overview

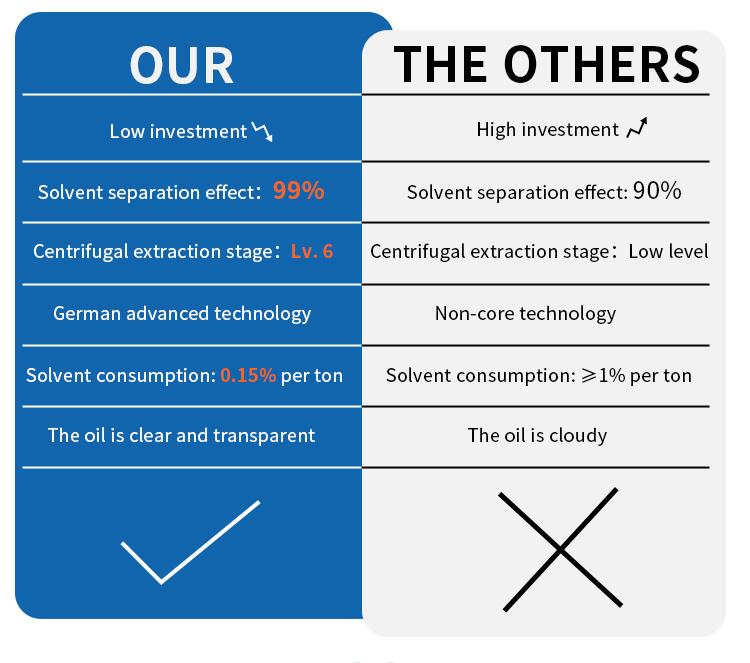

"Our company’s multi-stage solvent extraction and refining equipment utilizes a targeted solvent blending process and a closed-loop solvent regeneration system to produce API VI ultra-high viscosity index base oils, achieving a solvent recovery rate of about 98%, meeting the strict requirements for high-end lubricants, synthetic materials, and specialty chemicals."

Base oil extraction equipment has the following advantages:

1. High-efficiency separation

(1) It can accurately separate different components in the base oil, effectively removing impurities and improving the purity of the base oil.

(2) Compared with traditional methods, the separation efficiency is higher, and a large amount of raw materials can be processed in a shorter time.

2. High product quality

(1) The extracted base oil has stable quality and good performance. It can meet the production needs of various high-end lubricating oil products.

(2) Effectively removes undesirable components such as resin and asphalt, giving the base oil better oxidation resistance, low-temperature fluidity, and other performance indicators.

3. Environmentally friendly and energy-saving

(1) It recycles waste lubricating oil, reducing environmental pollution. It avoids the arbitrary discharge and disposal of waste oil, reducing environmental risks.

(2) Some extraction processes have relatively low energy consumption, and the solvent can be recycled and reused, reducing energy consumption and production costs.

4. Flexible operation

(1) According to different raw material properties and product requirements, process parameters and solvent selection can be adjusted to adapt to various types of base oil extraction needs.

(2) The equipment can be operated continuously or intermittently to meet the production requirements of different scales.

5. Good economic benefits

(1) Extracting base oil from waste lubricating oil reduces reliance on new crude oil resources and saves resource procurement costs.

(2) The high-quality base oil produced has high market value and can bring good economic benefits to the enterprise.

The application fields of base oil extraction equipment mainly include the following aspects:

1. Lubricant production

(1) Used to produce various types of lubricating oils, such as industrial lubricating oils and automotive lubricating oils. The high-quality base oil obtained through extraction can be blended into lubricating oil products with excellent performance to meet the lubrication needs of different mechanical equipment.

(2) Provides high-quality base oil raw materials for the research and development and production of high-end lubricating oils, improving the quality and performance of lubricating oils.

2. Waste lubricating oil regeneration

(1) Recycles and regenerates waste lubricating oil to extract reusable base oil. This not only reduces the pollution of waste oil to the environment but also achieves resource recycling and reduces production costs.

(2) Waste lubricating oil regeneration enterprises widely use base oil extraction equipment to convert recovered waste oil into valuable base oil and re-enter the market.

3. Petrochemical industry

(1) In the petroleum refining process, base oil extraction equipment can be used to optimize the product structure and improve the yield and quality of base oil. For example, extracting high-quality base oil from vacuum gas oil provides high-quality raw materials for subsequent chemical production.

(2) Combined with other petrochemical processes to achieve comprehensive resource utilization. For example, blending the extracted base oil with other petrochemical products to produce special oil products or chemical intermediates.

4. Special oil production

(1) Used to produce special lubricating oils, such as high-temperature lubricating oils, low-temperature lubricating oils, and food-grade lubricating oils. These special oil products have high requirements for the quality of base oil, and base oil extraction equipment can meet their strict performance requirements.

(2) Production of metalworking fluids, rust-preventive oils, and other special oil products. Base oil, as one of the main components of these oil products, its quality directly affects the performance of the product. High-quality base oil extracted through extraction equipment can improve the processing performance and protective effect of special oil products.

- PRODUCT

Technical services

Pre-sales Service

*We offer a variety of pre-sales services, such as developing investment budgets and manufacturing plans, enabling clients to make reasonable plans at a lower cost.

*Investment Budget: We provide services such as product profit analysis, machine recommendations and related budgets, and human resource allocation and budget preparation.

*Factory Planning: We provide services such as equipment library dimensions, equipment layout design, and workshop construction suggestions.

After-sales Support

*We provide free training to our clients, enabling them to independently use and maintain the machines.

*We will promptly answer our clients' technical questions and, if necessary, provide on-site guidance and assistance.

*If clients need new equipment, additions, or modifications, we will provide free technical guidance.

*All machines come with lifetime free technical assistance.

*All major machine components have a warranty of up to 24 months. Consumable parts have a 12-month warranty.

- VBOLT

Related product recommendations

Waste oil regeneration diesel equipment

Base oil solvent extraction equipment

Lubricating oil blending equipment

Used oil re-refining base oil equipment

- I WANT TO CONSULT

I want to consult

During the process of browsing our products, is there anything that you are particularly satisfied with or that needs to be improved? Your consultation or suggestions will directly help us improve product and service quality and bring you a more intimate experience.

* Please fill in the above fields (* indicates required fields), and we will reply to your feedback as soon as possible.

FAQ

Please refer to the following instructions for your questions