06

2024

-

11

How to use a backwashing filter? Remember these points, and operation will not be a worry

Author:

Backwashing filters are now one of the important environmental protection equipment in wastewater treatment, and they are well-known for their efficient wastewater treatment capabilities. However, in practical applications, many people are still confused, and many people don't know how to use this new type of equipment.

Let's take a look together. We have summarized the detailed operation process, hoping to help you.

I. How to operate the backwashing filter

1. Check whether all components are installed correctly: Before starting the backwashing filter, the system pipeline needs to be checked to ensure that the inlet and outlet valves and various lines are in normal operation.

2. Flush the system pipeline: Turn off the inlet and outlet valves, and open the isolation equipment and bypass valves to flush the backwashing filter pipeline.

3. Adjust the valve: Open the inlet and outlet water valves, and temporarily close the drain valve and bypass valve.

4. Connect the power to the control box: After everything is ready, turn on the power switch of the control box and power on to the running state.

5. Select the control method: The backwashing filter has multiple control methods, such as pressure difference control (with 0.05MPa as the critical value, the machine starts to drain when this value is reached), timing control (cleaning time and cleaning cycle are adjustable), manual control (with a drainage button), and remote control. We can choose the appropriate control method according to our own situation.

II. What are the precautions for using the backwashing filter?

1. Pay attention to the installation direction of the equipment. Generally, when installing the backwashing filter, it is necessary to adjust it in time according to the actual situation, and the equipment must be connected according to the direction of the inlet and outlet ports and the pipeline.

2. The net distance between equipment is not less than 1500 mm, and the space for maintenance around the equipment should be not less than 500 mm.

3. Regularly clean the filter element impurities. Impurities will accumulate in the backwashing filter during operation, and when there are too many impurities, it will affect the efficiency of wastewater treatment, so the filter element impurities need to be processed regularly.

4. Check and replace wearing parts. The backwashing filter can be said to be closely related. When you find that a certain part of the equipment is damaged or deformed, you need to stop the operation of the machine and immediately replace the parts.

5. Keep the controller dry. Pay attention to the dry state of the equipment whether it is plugged in or in operation, and do not touch water, which may cause accidents.

6. Use according to the rated power. When the backwashing filter is running, it can only be adjusted according to the voltage rating specified on the nameplate, and it must not be misused.

III. What fields is the backwashing filter suitable for?

1. Usage function

The functions of the backwashing filter are mainly reflected in three points. For example, self-cleaning filter screens, no need to equip a separate cleaning system; using pressure difference to set the set value, automatic backwashing can be realized; continuous water supply can be realized, and the machine body has multiple filter screens working at the same time.

2. Application areas

Backwashing filters are often used in industrial and civil cooling water treatment, industrial cooling circulating water systems; hot water circulating systems for heating in heating systems; circulating systems for bathing and heating using geothermal water; central air conditioning, chillers, refrigeration machine cooling and freezing circulating water systems, etc.

Latest News

2024-11-06

Why does waste slag coke?

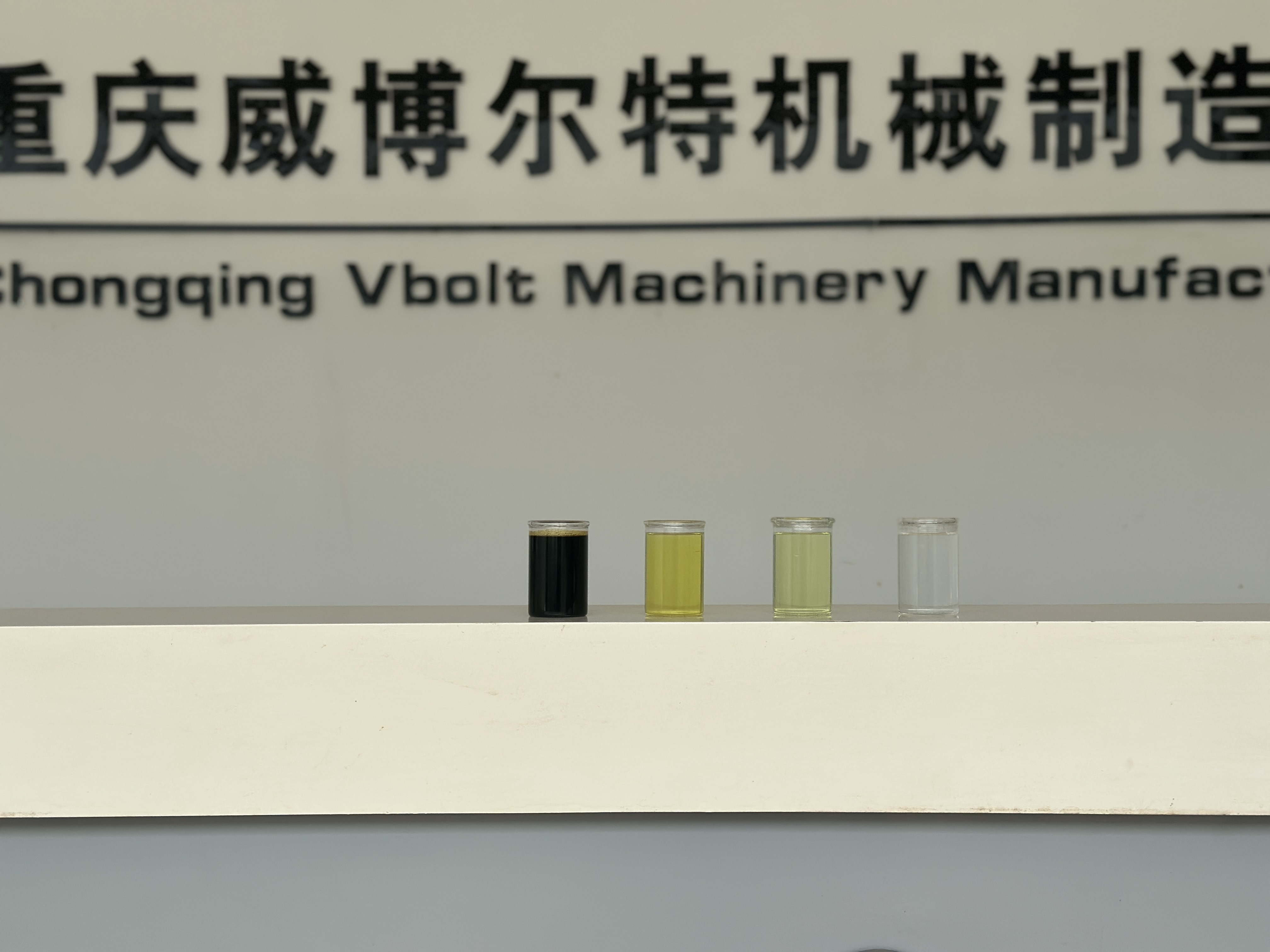

Used lubricating oil contains a variety of impurities, and due to the presence of detergent dispersants (a commonly used additive)

2024-11-06

What is the working principle of a vacuum oil filter?

Vacuum oil filter is suitable for degassing, impurity removal, water filtration and purification, and waste oil regeneration of industrial oils such as transformer oil, turbine oil, lubricating oil, and hydraulic oil.

2024-11-06

Application of fiber ball filter in oilfield wastewater treatment

In oilfield produced water treatment, there is a problem of substandard water quality. There are many factors contributing to this situation, the most important of which is the filter problem. Filtration is the last resort for removing suspended solids and oil.

2024-11-06

How to use a backwashing filter? Remember these points, and operation will not be a worry

Backwashing filters are now one of the important environmental protection equipment in wastewater treatment, and are well-known for their efficient wastewater treatment capabilities.