Application Areas

Design concept

Diesel quality

Technical services

- PRODUCT

Application Areas

Diesel, as an important energy resource, has a wide range of uses in modern society. Its main applications include, but are not limited to, the following aspects:

1. Transportation

Diesel is the main fuel for heavy-duty vehicles like trucks, buses, trains, and ships, providing the necessary power for long-distance transport and heavy loads. Its high energy density and combustion efficiency make it essential in these sectors. Additionally, some small and high-performance cars have also adopted diesel for its low energy consumption.

2. Agricultural Machinery

Diesel is essential for powering agricultural machinery like tractors and harvesters, which are crucial for processes such as tillage, sowing, and harvesting. Its stability and efficiency are vital for smooth agricultural production.

3. Construction Machinery

Diesel is also the main fuel for construction machinery such as excavators, bulldozers, and loaders. On construction sites, these machines require long hours of high-intensity operation, and the high energy output and reliability of diesel can meet these needs, ensuring construction efficiency and safety.

4. Power Generation

Diesel generator sets are widely used in power plants, industrial power supply, and power supply in areas without power grids. In emergencies or when the mains power supply is insufficient, diesel generator sets can be quickly started to provide stable power support, ensuring the normal operation of production and life.

5. Fisheries

Diesel engines power fishing vessels and onboard equipment, providing the high-intensity support needed for long hours at sea. Their reliability and durability ensure stable fishing production.

6. Industrial Equipment

Diesel engines drive industrial equipment like pumps, compressors, and excavators, crucial for production. Their stability and efficiency ensure normal operation and enhance production efficiency.

7. Aviation Fuel

Although the application of diesel in aviation is relatively limited, some specific types of aircraft or drones also use diesel as fuel. The high density and high energy of diesel allow aircraft to achieve longer flight distances after a single refueling, reducing the number of fuel replenishments and downtime.

8. Heating

Diesel combustion generates heat that can warm buildings and equipment, offering a comfortable environment for residents and industries. It has higher thermal efficiency and lower emissions compared to other heating methods.

9. Backup Power

Diesel generator sets serve as backup power for enterprises, hospitals, banks, and data centers, ensuring continued operation during mains power interruptions.

10. Special Vehicles

Diesel powers not only common transportation vehicles but also special ones like fire trucks, police cars, and ambulances. These vehicles require quick response and efficient operation during emergencies, and diesel engines provide the necessary power and reliability.

Diesel is widely used due to its efficiency, stability, and cost-effectiveness. As technology advances and environmental regulations tighten, its applications will further expand and improve.

- PRODUCT

Design concept

1. Overview of Waste Oil Regeneration Diesel Equipment

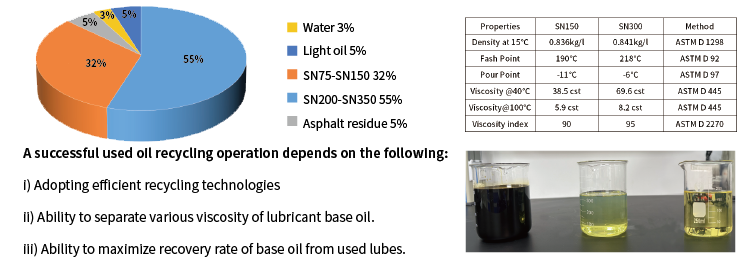

Waste oil regeneration diesel equipment converts waste oily substances into usable diesel fuel through physical, chemical, or biological processes. The process includes waste oil collection, pretreatment, catalytic conversion, and purification. Ultimately, waste oil is transformed into regenerated diesel fuel, achieving resource reuse and environmental protection.

2. Working Principle of Waste Oil Regeneration Diesel Equipment

The waste oil regeneration diesel equipment operates on complex catalytic conversion technology. Initially, collected waste oil undergoes pretreatment, including filtration, dehydration, and impurity removal, to eliminate solid impurities and harmful substances. The pretreated oil is then processed in a reactor under specific temperature, pressure, and catalyst conditions, leading to chemical reactions like cracking and hydrodesulfurization, resulting in a pure hydrocarbon mixture. Finally, this mixture is refined through rectification and separation to produce regenerated diesel fuel that meets standards.

3. Advantages of Waste Oil Regeneration Diesel Equipment

The use of waste oil regeneration diesel equipment offers significant advantages. It transforms waste into valuable resources, alleviating petroleum resource tension and promoting recycling. Environmentally, it reduces pollution risks associated with waste oil landfill and incineration. Economically, it produces high-quality regenerated diesel fuel, benefiting enterprises and lowering fuel costs for users.

4. Technological Challenges and Development Trends of Waste Oil Regeneration Diesel Equipment

Waste oil regeneration diesel equipment has advantages but faces challenges in technological development. The complex composition of waste oil necessitates varied processing technologies and catalysts, raising equipment complexity and costs. Additionally, ensuring the quality stability and long-term safety of regenerated diesel fuel remains a concern.

- PRODUCT

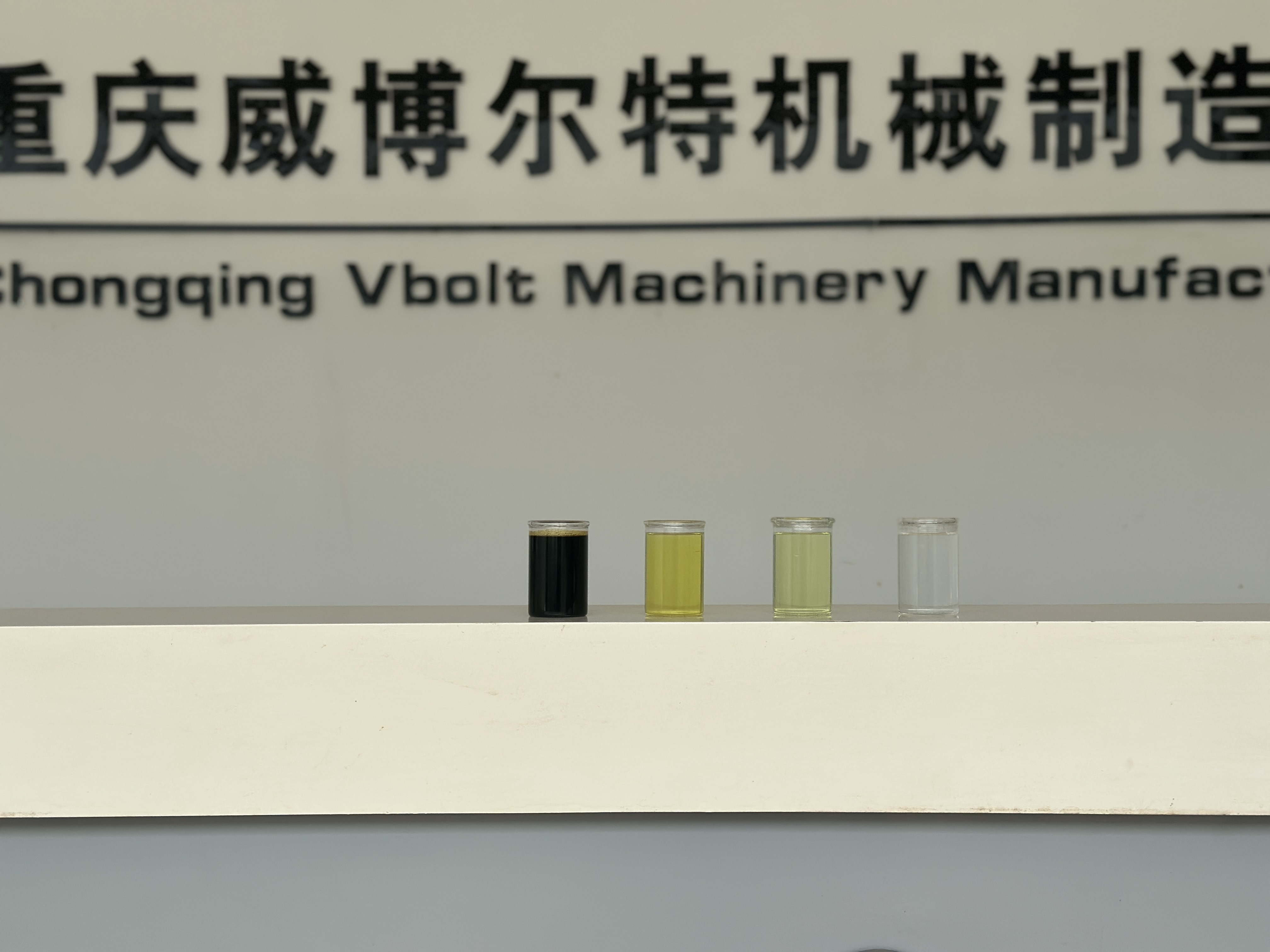

Diesel quality

In summary, the fact that the equipment can regenerate diesel fuel to meet the Euro IV standard is a significant technological achievement. It helps reduce environmental pollution, promotes sustainable development, and demonstrates the equipment's leading position in diesel regeneration technology.

- PRODUCT

Technical services

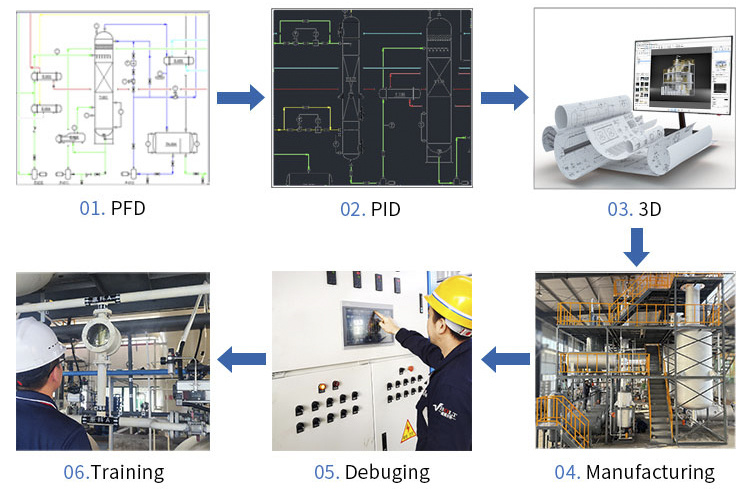

Pre-sales Service

*We offer a variety of pre-sales services, such as developing investment budgets and manufacturing plans, enabling clients to make reasonable plans at a lower cost.

*Investment Budget: We provide services such as product profit analysis, machine recommendations and related budgets, and human resource allocation and budget preparation.

*Factory Planning: We provide services such as equipment library dimensions, equipment layout design, and workshop construction suggestions.

After-sales Support

*We provide free training to our clients, enabling them to independently use and maintain the machines.

*We will promptly answer our clients' technical questions and, if necessary, provide on-site guidance and assistance.

*If clients need new equipment, additions, or modifications, we will provide free technical guidance.

*All machines come with lifetime free technical assistance.

*All major machine components have a warranty of up to 24 months. Consumable parts have a 12-month warranty.

Previous

- VBOLT

Related product recommendations

Waste oil regeneration diesel equipment

Base oil solvent extraction equipment

Lubricating oil blending equipment

Used oil re-refining base oil equipment

- I WANT TO CONSULT

I want to consult

During the process of browsing our products, is there anything that you are particularly satisfied with or that needs to be improved? Your consultation or suggestions will directly help us improve product and service quality and bring you a more intimate experience.

* Please fill in the above fields (* indicates required fields), and we will reply to your feedback as soon as possible.

FAQ

Please refer to the following instructions for your questions