06

2024

-

11

Application of fiber ball filter in oilfield wastewater treatment

Author:

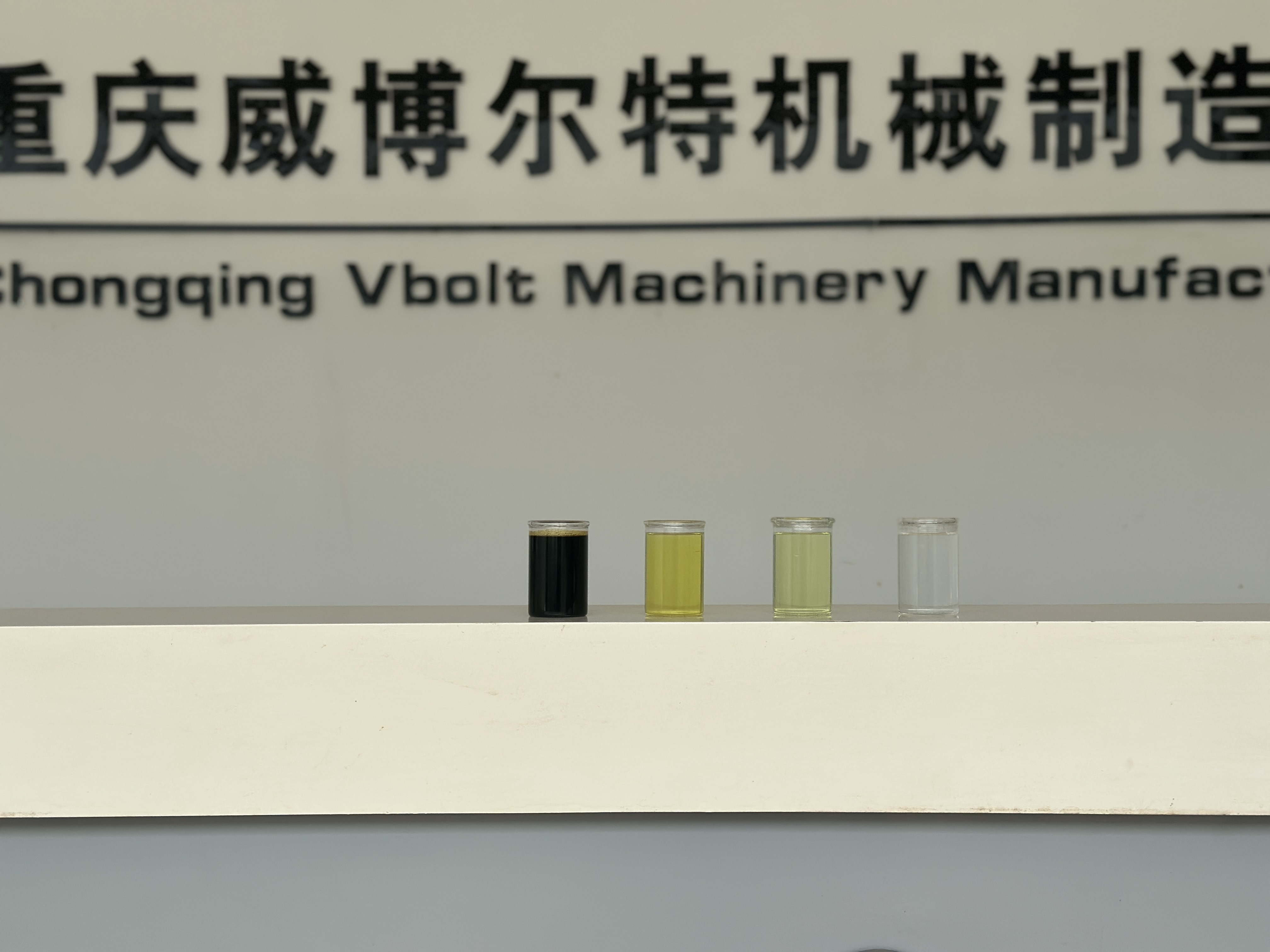

In oilfield produced water treatment, there is a problem of substandard water quality. There are many factors contributing to this situation, the most important of which is the filter problem. Filtration is the final means of removing suspended solids and oil, i.e., intercepting and adsorbing suspended particles, oil, and algae in the wastewater to meet the relevant standards.

The application of fiber ball filters can effectively improve the treatment effect.

Analysis of the characteristics of fiber ball filters

The fiber diameter is relatively thin, and the surface area per gram can reach 2000㎡. After effective stacking, the porosity can be guaranteed to be higher than 80%, and the interception effect is better than that of traditional filter media.

Fiber ball filters are hydrophilic and oil-repellent. When they encounter water, a large number of water molecules gather on the surface of the fibers, forming a water film on the surface, which acts as a good isolation layer between the oil and the fiber balls.

Through backwashing, the oil stains on the surface of the fiber balls can be cleaned, and it has renewable performance.

Working principle of fiber ball filter

Solid suspended matter will accumulate on the surface of the medium, and a filter cake will be formed through bridging and filtration, improving the filtration accuracy. At the same time, the porosity of the filter material will also decrease, increasing the filtration resistance.

When the resistance increases to a certain extent, the bridging relationship will be destroyed by the impact of subsequent suspended particles, and new larger suspended particles will replace the destroyed bridging relationship to continue intercepting and filtering the suspended matter in the oily wastewater.

Comparison of fiber ball filters with other filter media

Walnut shell filter media: strong adsorption capacity, high hardness, wear resistance, large filtration capacity, but the effect of removing solid suspended matter in oily wastewater is poor.

Double-layer filter media filter: strong dirt holding capacity, simple operation, easy to manage, suitable for deep wastewater treatment.

Quartz sand filter: It is the most widely used equipment in oilfield water treatment systems at present. Due to its simple structure, easy maintenance, and convenient operation, it has a good wastewater treatment effect.

As a new type of fine filtration equipment for oilfield wastewater, fiber ball filters have obvious advantages: including hydrophilicity and oil repellency, large surface area, high porosity, and good regeneration performance. The advantages are more obvious in the treatment of wastewater from low-permeability oil layers, and high-precision filtration can be achieved, which plays an important role in improving the sustainability of oilfield development operations.

Latest News

2024-11-06

Why does waste slag coke?

Used lubricating oil contains a variety of impurities, and due to the presence of detergent dispersants (a commonly used additive)

2024-11-06

What is the working principle of a vacuum oil filter?

Vacuum oil filter is suitable for degassing, impurity removal, water filtration and purification, and waste oil regeneration of industrial oils such as transformer oil, turbine oil, lubricating oil, and hydraulic oil.

2024-11-06

Application of fiber ball filter in oilfield wastewater treatment

In oilfield produced water treatment, there is a problem of substandard water quality. There are many factors contributing to this situation, the most important of which is the filter problem. Filtration is the last resort for removing suspended solids and oil.

2024-11-06

How to use a backwashing filter? Remember these points, and operation will not be a worry

Backwashing filters are now one of the important environmental protection equipment in wastewater treatment, and are well-known for their efficient wastewater treatment capabilities.