06

2024

-

11

What is the working principle of a vacuum oil filter?

Author:

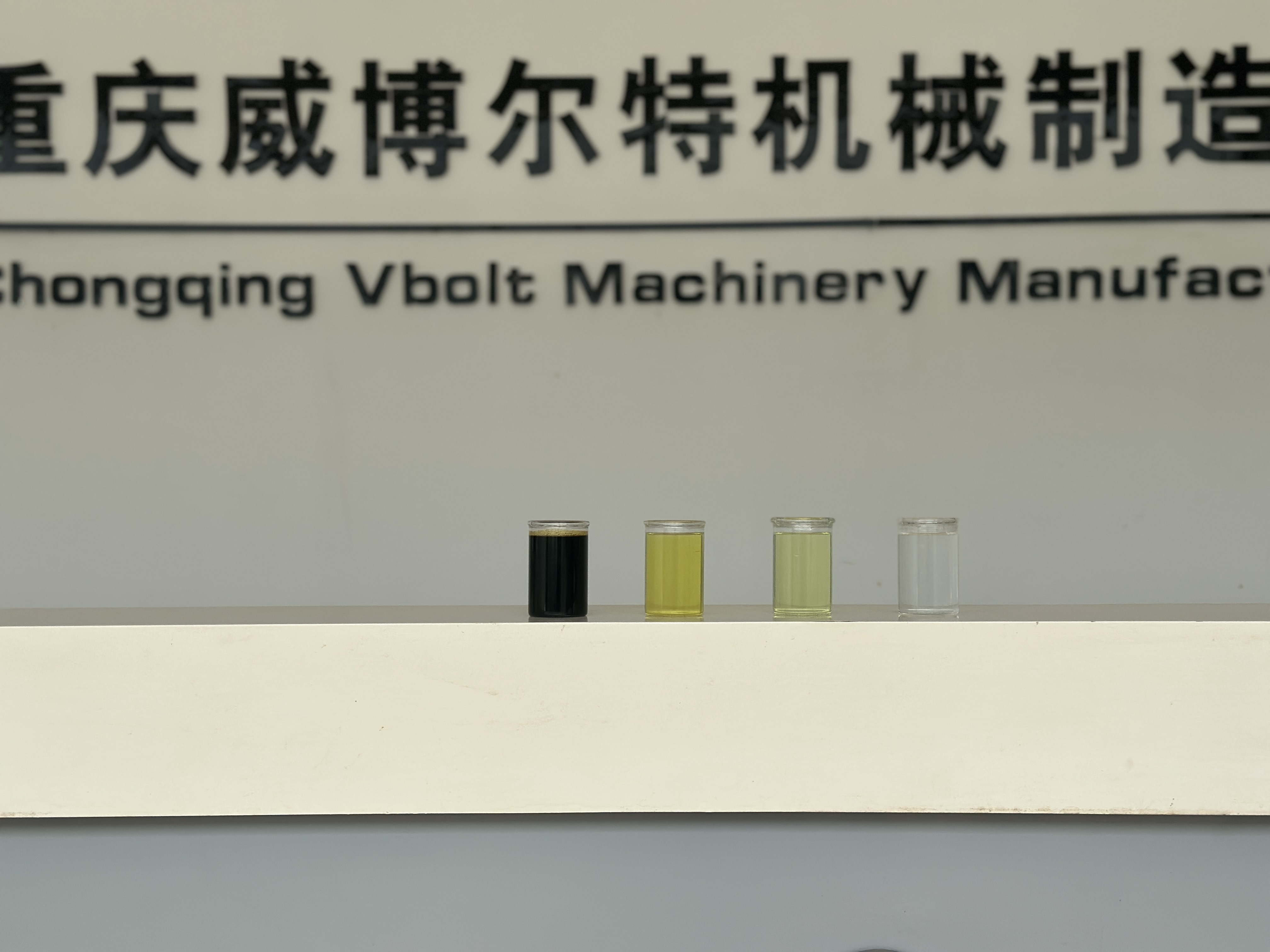

Vacuum oil purifier Suitable for degassing, impurity removal, water filtration, purification, and waste oil regeneration of industrial oils such as transformer oil, turbine oil, lubricating oil, and hydraulic oil. It overcomes the shortcomings of general vacuum oil purifiers that are only suitable for removing micro-water oil treatment and is an ideal special equipment for running oil purification. Working principle: Atomized oil is dehydrated and degassed under vacuum. Three sets of filters can filter out various fine solid impurities, and special regeneration adsorbents can remove chemical residues in the oil.

Now let's introduce the structure and characteristics of the vacuum oil purifier: The vacuum oil purifier is composed of main components such as heating, filtration, vacuum, condensation, and adsorption regeneration. It is divided into: heating system, filtration system, vacuum atomization system, oil supply system, and electrical control system. Due to different manufacturer requirements, the vacuum oil purifier can also add acid removal and decolorization adsorption devices. Advantage 1: Multi-purpose, fully functional. It can dehydrate and degas, three sets (coarse, medium, fine) of filters, adsorption regeneration integrated process treatment, and can independently provide vacuum dehydration and degassing, impurity removal, and regeneration adsorption functions. Advantage 2: Safe and reliable. Pressure, temperature, and liquid level have clear data indication and mechanical automatic control. Feature 3: High efficiency, economical, and low operating cost. It is a device with complete functions and advanced performance among similar oil treatment products. Advantage 3: Reasonable design structure.

Easy to move or use online. First, let's look at what oil cleanliness is: Oil cleanliness refers to the amount of remaining dirt in the oil after use or after cleaning equipment. Generally speaking, the content of pollutants in oil is generally measured by indicators such as the type, shape, size, quantity, and weight of pollutants. The indicators used depend on the harm and impact of different pollutants on the oil function and the control requirements of the equipment cleanliness.

Secondly, let's look at what the filtration accuracy of the oil purifier is: Filtration accuracy refers to the filtration efficiency or capacity counted in microns (u) particles. Generally speaking, the so-called filtration accuracy in China's oil purifier industry generally refers to the accuracy of oil purifiers, filters, etc., which actually refers to the pore size of the filter element. Of course, it can also be said that it is waste oil containing impurities, and the size of large particles allowed to pass through the filter screen. Conclusion: Through the above theoretical analysis, we can know that cleanliness and filtration accuracy are not the same concept at all. Cleanliness indicates the content of oil particles; filtration accuracy describes the filtration capacity of oil purifiers, filters, filters, oil purifiers, etc., or indicates the accuracy of the filter element, and the size of particles that can be accommodated. The objects described by the two are different. Cleanliness describes oil pollution, and filtration accuracy shows the filtration capacity of the oil purifier. Of course, by meeting a certain filtration accuracy, the filtered oil reaches the corresponding cleanliness to meet the equipment requirements, indicating that the filtered oil meets the requirements.

Latest News

2024-11-06

Why does waste slag coke?

Used lubricating oil contains a variety of impurities, and due to the presence of detergent dispersants (a commonly used additive)

2024-11-06

What is the working principle of a vacuum oil filter?

Vacuum oil filter is suitable for degassing, impurity removal, water filtration and purification, and waste oil regeneration of industrial oils such as transformer oil, turbine oil, lubricating oil, and hydraulic oil.

2024-11-06

Application of fiber ball filter in oilfield wastewater treatment

In oilfield produced water treatment, there is a problem of substandard water quality. There are many factors contributing to this situation, the most important of which is the filter problem. Filtration is the last resort for removing suspended solids and oil.

2024-11-06

How to use a backwashing filter? Remember these points, and operation will not be a worry

Backwashing filters are now one of the important environmental protection equipment in wastewater treatment, and are well-known for their efficient wastewater treatment capabilities.