Application Areas

Design concept

Base oil quality

Technical services

- PRODUCT

Application Areas

Base oils have a very wide range of applications, covering multiple industries and fields. The following are the main application areas of base oils:

1. Lubricant field

Base oil is the main component of lubricating oil. By adding different additives, various types of lubricating oil can be produced, such as engine oil, gear oil, and grease. These lubricating oils play a role in reducing friction and protecting mechanical parts in the automotive, machinery, shipping, and aviation industries.

2. Fuel field

Some base oils, such as diesel and gasoline, are important components of fuel. Their quality and quantity directly affect the performance and quality of the fuel. Fuel base oils are most widely used in vehicles and other transportation tools, and can be used to manufacture various types of gasoline and diesel fuel to meet the needs of different environments and demands. At the same time, due to their low volatility and high purity, fuel base oils can also be used to manufacture marine fuels, improving the reliability and safety of ship navigation.

3. Pharmaceutical field

Some base oils have medicinal value and can be directly used in the production of medicines or as solvents and carriers in pharmaceutical production. For example, Flaxseed oil is rich in Omega-3 fatty acids, which are beneficial to cardiovascular health; evening primrose oil helps alleviate premenstrual syndrome symptoms. 。

- PRODUCT

Design concept

The design concept of waste oil regeneration base oil equipment mainly revolves around the core elements of efficiency, environmental protection, economy, and safety:

Efficiency

1. Advanced Technology

Waste oil regeneration base oil equipment uses vacuum molecular distillation technology, especially high-vacuum short-path distillation technology. This technology breaks through the limitations of traditional distillation relying on boiling point differences for separation and can achieve efficient material separation at a relatively low temperature (approximately 350℃).

2. High Recovery Rate

Through advanced process technology and equipment design, the recovery rate of waste oil regeneration base oil equipment exceeds 85%, greatly improving the utilization rate of waste oil and grease.

Environmental Protection

1. Reduce Pollution

Waste oil regeneration base oil equipment can convert waste oil and grease into valuable gasoline, diesel, and base oil, thereby reducing the pollution of waste oil and grease to the environment.

2. **Energy Saving and Consumption Reduction**

The equipment emphasizes energy saving and consumption reduction in its design. By optimizing the process flow and equipment parameters, it reduces energy consumption and emissions, meeting environmental protection requirements.

Economy

1. Low Cost

The operating cost of waste oil regeneration base oil equipment is relatively low, mainly due to its high recovery rate and energy-saving and consumption-reducing design.

2. High Returns

By recovering and regenerating waste oil and grease, the equipment can produce high-quality base oil, bringing significant economic benefits to the enterprise.

Flexibility and Adaptability

1. Wide Processing Range

Waste oil regeneration base oil equipment can process various types of waste oil and grease, such as waste engine oil, industrial waste lubricating oil, waste hydraulic oil, waste diesel, waste gasoline, tire oil, etc., and has wide applicability.

2. Easy Maintenance

The equipment design is simple and clear, easy to maintain and maintain, reducing the maintenance cost of the enterprise.

In summary, the design concept of waste oil regeneration base oil equipment embodies the core elements of efficiency, environmental protection, economy, safety, flexibility, and adaptability. The implementation of these design concepts not only improves the utilization rate of waste oil and grease and the economic benefits of enterprises but also promotes the sustainable development of environmental protection.

- PRODUCT

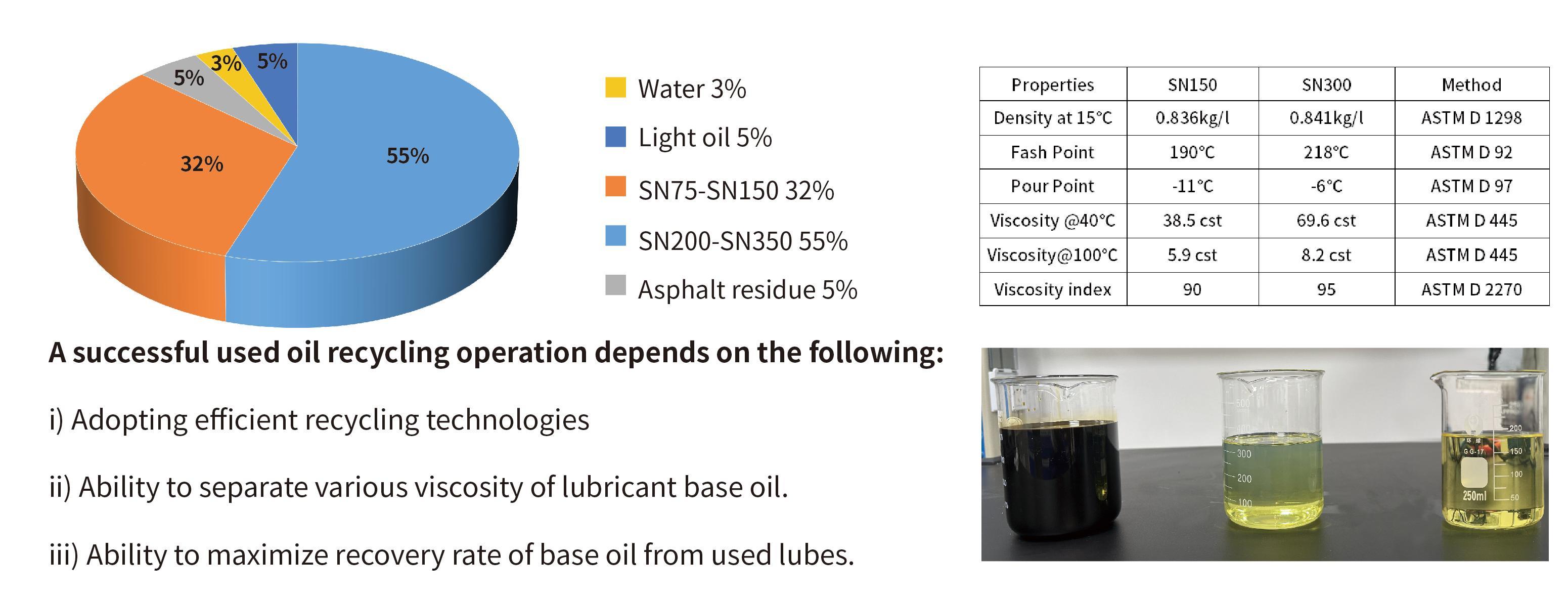

Base oil quality

- PRODUCT

Technical services

Pre-sales Service

*We provide various forms of pre-sales services, such as formulating investment budgets, manufacturing , allowing customers to make reasonable plans at a lower cost.

*Investment Budget: Provides product profit analysis, machine recommendations and related budgets, human resource allocation and budget preparation services.

*Factory Planning: Provides equipment library dimensions, equipment layout design, and workshop construction suggestions.

After-sales Support

*We provide customers with free training , enabling them to independently use and maintain the machines.

*We will promptly answer customers' technical questions; if necessary, we will provide on-site guidance and assistance 。

*If customers need new equipment, additions, or modifications, we will provide free technical guidance.

*All machines are provided with lifetime free technical assistance 。

*All major machine parts are warranted for up to 24 months. Consumable parts are warranted for 12 months.

Previous

Next

- VBOLT

Related product recommendations

Waste oil regeneration diesel equipment

Base oil solvent extraction equipment

Lubricating oil blending equipment

Used oil re-refining base oil equipment

- I WANT TO CONSULT

I want to consult

During the process of browsing our products, is there anything that you are particularly satisfied with or that needs to be improved? Your consultation or suggestions will directly help us improve product and service quality and bring you a more intimate experience.

* Please fill in the above fields (* indicates required fields), and we will reply to your feedback as soon as possible.

FAQ

Please refer to the following instructions for your questions