Lubricating oil blending equipment

Vbolt lubricant blending equipment technology provides an engine oil mixing system. The reaction tank is equipped with quick heating pipes, avoiding the large energy loss caused by in-tank heating.

Each pipeline is designed with its independence and precise control needs in mind, therefore, they are all equipped with individual control valves, flow meters, and check valves to ensure extremely high control accuracy during fluid transfer. Control valves precisely adjust fluid flow and pressure in pipelines, while flow meters monitor and record real-time flow data for production optimization. Check valves prevent backflow, avoiding equipment damage and production accidents. These components enable precise control and monitoring of pipelines, ensuring the safe and efficient operation of the fluid transfer system.

Detailed analysis of the main parts is as follows:

Additive System: The system's core function is to mix various additives, such as antioxidants, rust inhibitors, anti-wear agents, and detergent dispersants, to enhance the final product's performance. By precise metering and proportioning, the system ensures that each additive is combined in the correct ratio to achieve the desired effects.

Heating System: This system utilizes electric heating, offering easy control, uniform and rapid heating. Precise temperature regulation prevents high temperatures from damaging oil performance, ensuring stability during heating. Additionally, electric heating is energy-efficient and eco-friendly, lowering energy use and environmental impact.

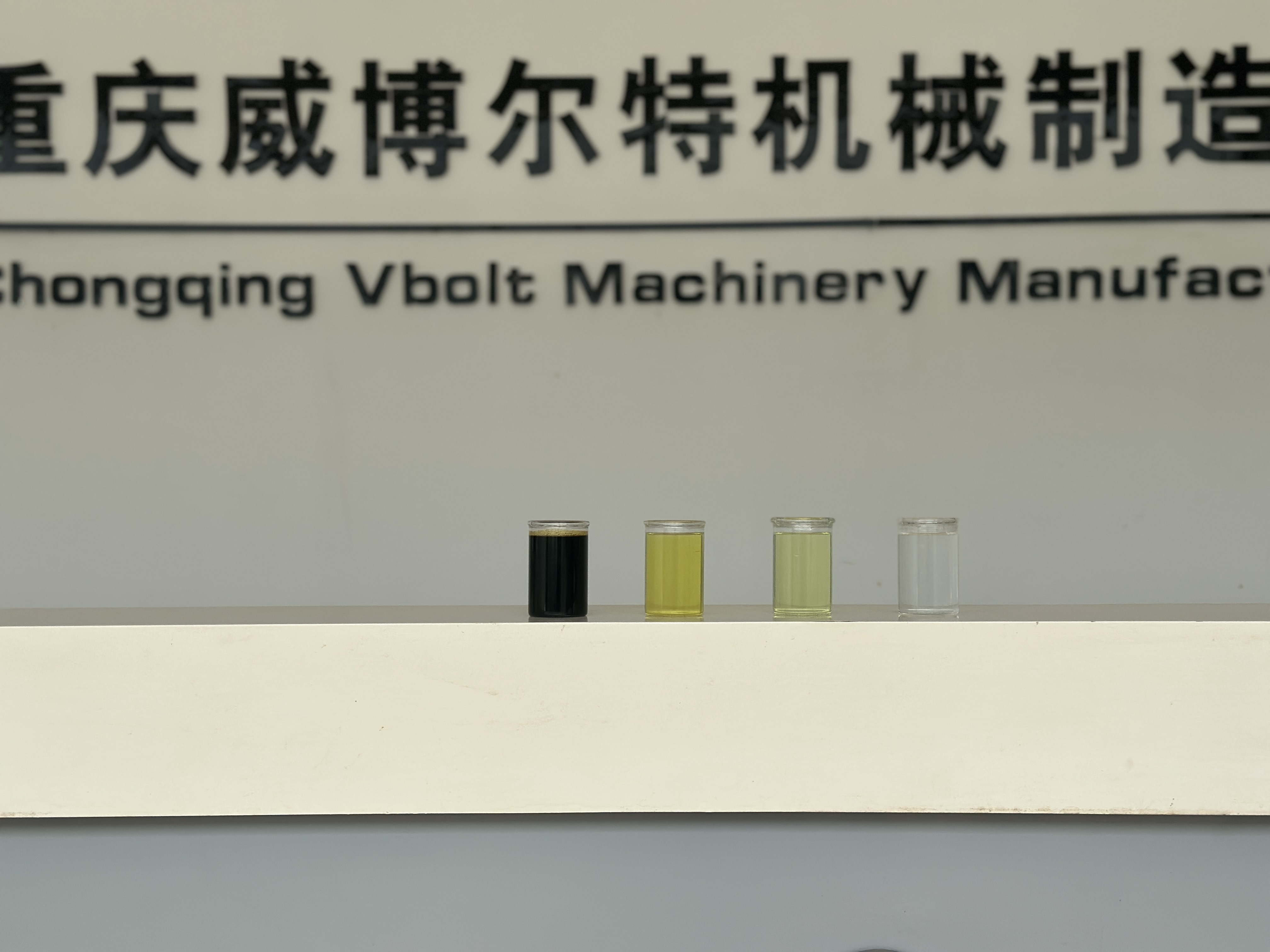

Mixing System:The system primarily heats base oil and mixes additives in precise proportions, ensuring thorough and even mixing through continuous stirring. By controlling temperature and stirring speed, it guarantees stable performance of the final product for various applications. The reaction system plays a crucial role by further mixing and reacting the oil products to ensure complete dissolution and distribution of additives. It continuously monitors and adjusts parameters like temperature and pressure to facilitate the reaction while also fine-tuning the oil products to enhance their overall performance.

Application Areas

Design concept

Technical services

- PRODUCT

Application Areas

Lubricating oil is widely used in various mechanical equipment as a liquid or semi-solid lubricant. Its main functions are to reduce friction, minimize wear, cool equipment, and protect metal surfaces. Following are some of the main application areas and their outstanding advantages:

Application Areas

1. Automotive Industry

- Engine oil: Used to lubricate internal engine parts, reduce wear, and improve engine efficiency.

- Gear oil: Used for gear lubrication in automotive transmissions and drive axles.

- Brake fluid: Transmits pressure in the braking system to ensure proper braking system operation.

2. Industrial Manufacturing

- Lubrication of machinery and equipment: Such as machine tools, injection molding machines, compressors, etc.

- Metalworking fluids: Such as cutting oils and grinding fluids, used for lubrication and cooling during metal processing.

3. Aerospace

- Engine lubricating oil: Used for lubrication and cooling of aircraft and rocket engines.

- Transmission system oil: Used for lubrication and transmission in aircraft transmission systems.

4. Power Industry

- Transformer oil: Used for insulation and cooling of power transformers.

- Switch oil: Used for insulation and arc extinguishing in high-voltage switchgear.

- PRODUCT

Design concept

1. Automated Control

- Lubricating oil blending equipment generally uses automated control systems, such as automatic bucket (200L additive) systems (DDS), automatic ball cleaning systems, and fully automatic manifolds, to reduce manual operation and improve production efficiency.

2. Rapid Blending

- Using automatic batch blending technology (ABB) and online blending technology (SMB) can quickly, accurately, and efficiently blend high-quality products, reducing blending losses and improving the first-pass yield.

Achieve Environmental Protection and Sustainable Development

1. Green Lubrication

- Modern lubricating oil blending equipment emphasizes the concept of green lubrication in its design, using high-efficiency lubricants, monitoring and regeneration technologies, etc., to extend the service life of lubricating oil and reduce environmental pollution.

2. Energy Saving and Emission Reduction

- The equipment uses energy-saving measures such as quantitative heating technology and variable frequency facilities for pumps in its design to reduce energy consumption and emissions, meeting the requirements of sustainable development.

In summary, the design concept of lubricating oil blending equipment covers multiple aspects, including improving production efficiency, reducing costs, ensuring product quality, and achieving environmental protection and sustainable development. The realization of these design concepts helps to enhance the competitiveness of lubricating oil production enterprises, meet market demand, and promote the sustainable development of the industry.

- PRODUCT

Technical services

Pre-sales Service

*We offer a variety of pre-sales services, such as developing investment budgets and manufacturing plans, enabling clients to make reasonable plans at a lower cost.

*Investment Budget: We provide services such as product profit analysis, machine recommendations and related budgets, and human resource allocation and budget preparation.

*Factory Planning: We provide services such as equipment library dimensions, equipment layout design, and workshop construction suggestions.

After-sales Support

*We provide free training to our clients, enabling them to independently use and maintain the machines.

*We will promptly answer our clients' technical questions and, if necessary, provide on-site guidance and assistance.

*If clients need new equipment, additions, or modifications, we will provide free technical guidance.

*All machines come with lifetime free technical assistance.

*All major machine components have a warranty of up to 24 months. Consumable parts have a 12-month warranty.

- VBOLT

Related product recommendations

Waste oil regeneration diesel equipment

Base oil solvent extraction equipment

Lubricating oil blending equipment

Used oil re-refining base oil equipment

- I WANT TO CONSULT

I want to consult

During the process of browsing our products, is there anything that you are particularly satisfied with or that needs to be improved? Your consultation or suggestions will directly help us improve product and service quality and bring you a more intimate experience.

* Please fill in the above fields (* indicates required fields), and we will reply to your feedback as soon as possible.

FAQ

Please refer to the following instructions for your questions