Company Profile

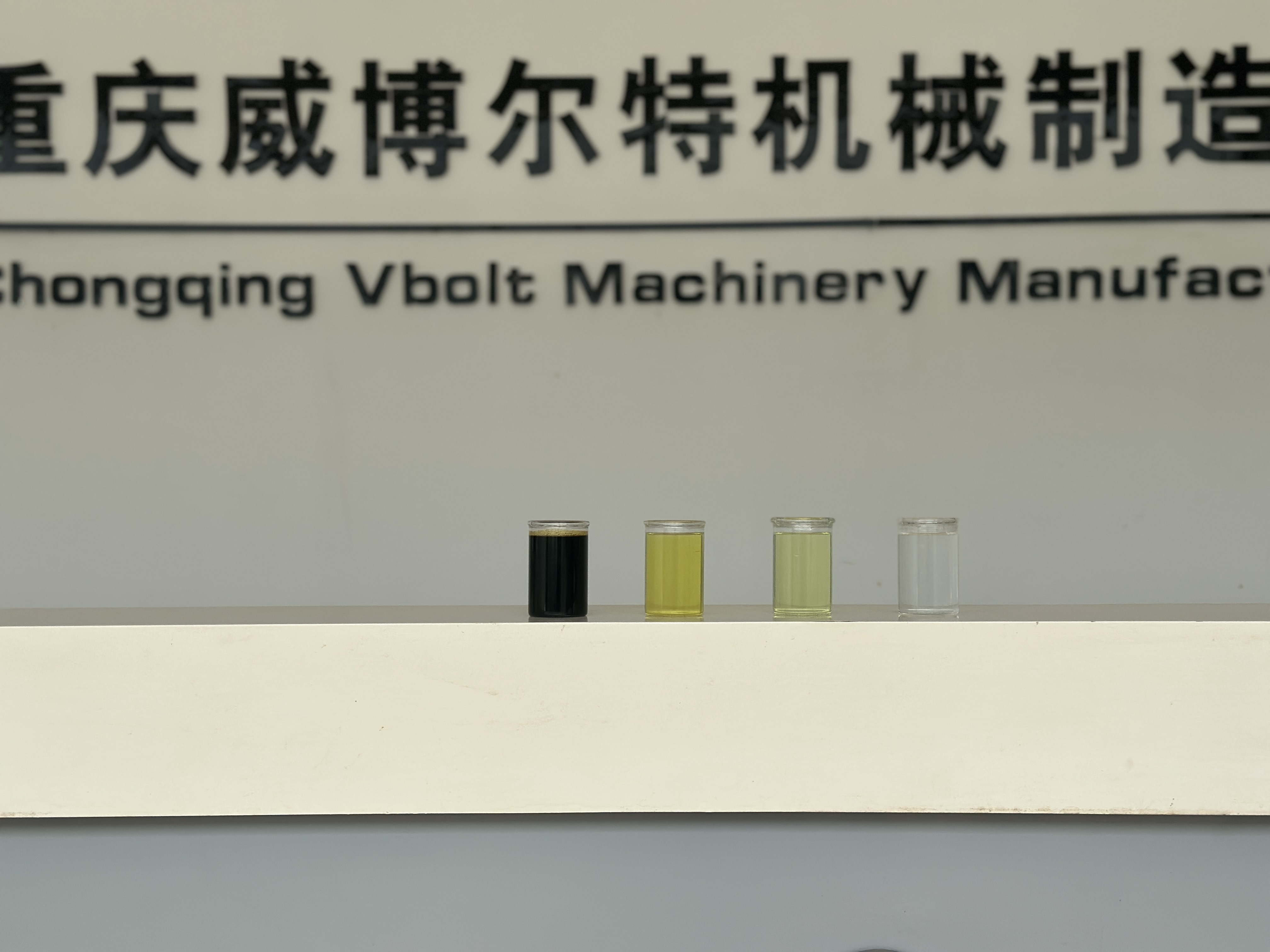

Chongqing Vbolt Machinery Co., Ltd. (a national high-tech enterprise) is a practitioner in the field of industrial lubricating oil regeneration technology, and is committed to building a clean energy circular economy ecosystem. The company uses independent innovation as its engine, integrating R&D, manufacturing, and service into a trinity. It has formed a complete technological closed-loop in the field of waste oil regeneration and lubricating oil treatment, covering pretreatment, regeneration, refining, and application. The core product system includes: waste oil regeneration diesel equipment sets, waste oil regeneration base oil distillation systems, lubricating oil solvent extraction devices, and intelligent lubricating oil blending equipment, aiming to provide global customers with full-industry chain technical solutions.

Quality Certification and Manufacturing Strength

The company strictly follows international standards and has passed ISO9001:2008 quality management system and ISO14001:2004 environmental management system double certifications. Core products have obtained EU CE certification. Relying on a digital production base of more than 4,000 square meters, equipped with a unique intelligent processing center and assembly line, it has built an integrated innovation platform of "production, education, research, and inspection". The company's technical team holds nearly 20 utility model patents, and its service network covers five continents. Products are exported to hundreds of countries, including Thailand and Algeria, and have also cooperated with many well-known domestic enterprises such as the State Grid and the State Power Investment Group.

Core Value System

Technology-driven Development Architecture

Building a three-level innovation system of "technology research and development-process optimization-product iteration", forming a differentiated competitive advantage with filtration technology as the core, intelligent control system as a feature, and environmentally friendly technology as an advantage. It is also equipped with a dedicated experimental workstation and an enterprise R&D center.

Full Life Cycle Quality Control

Innovatively implementing the "Three-Product Strategy" quality project (quality foundation - building a quality system based on military standards, quality control escort - establishing a raw material traceability to finished product tracking system, brand added value - pioneering a 72-hour full-load test run system for equipment), through SPC process control and MES system integration, realizing real-time monitoring of quality data, and achieving a product first-pass yield of 99.8%.

Empowering Organizational Management System

Implementing the "3E" management model (Empowerment, Efficiency, Evolution), establishing a dynamic adaptation mechanism for strategic goals, process systems, and talent development, creating a self-driven organization with industry benchmark significance, with an average per capita efficiency increase of 120% in the past three years.

Intelligent Service System

Building a "cloud + terminal" three-dimensional service network, creating a unique 135 rapid response mechanism: 1-hour technical response → 3-hour solution → 5-day on-site arrival. Establishing a global spare parts center warehouse, equipped with an AR remote diagnosis system, providing equipment life-cycle health management services. Customer satisfaction has remained above 98% for five consecutive years.

As a leading environmental protection and regeneration system comprehensive service provider in the industry, Vbolt, with the attitude of a "carbon seeker", is helping global customers achieve annual CO₂ emission reduction targets of hundreds of thousands or even millions of tons through continuous breakthroughs in waste oil resource utilization technology. The company is determined to become a technology source in the global industrial oil regeneration field, promoting the development of the circular economy towards high efficiency, intelligence, and low carbon.