22

2025

-

07

Application Case of Intelligent Waste Oil Regeneration Diesel Processing System Overall Solution

Author:

Project Overview

This project focuses on converting waste oil into high-quality clean diesel. By deploying the company's independently developed regenerated diesel equipment, a full-chain intelligent production system has been built, covering in-depth pretreatment of waste oil, core conversion, and refined product processing. The core objective is to solve key industry bottlenecks: "low conversion efficiency due to the complex and variable composition of waste oil," "high energy consumption and cost pressure during production," and "fluctuations in refined oil quality and difficulty in meeting standards." The goal is to achieve efficient, environmentally friendly, and high-value regeneration and reuse of waste oil.

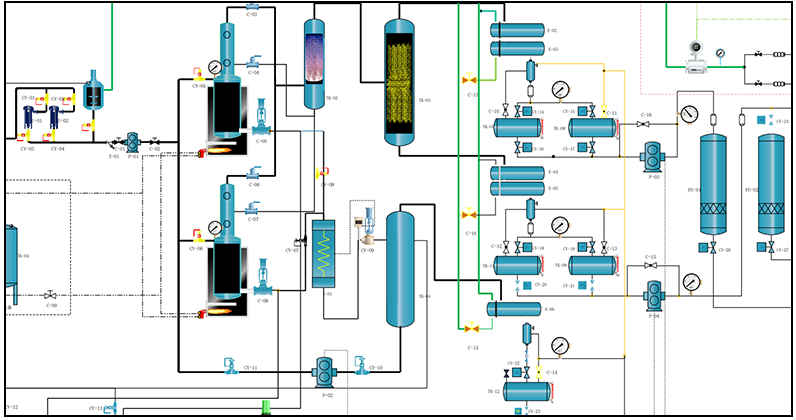

During implementation, customized pretreatment and impurity removal (fine filtration, centrifugal separation) and dehydration (atmospheric and reduced pressure, coalescence dehydration) process parameters are configured to address the differences in characteristics of different waste oils (such as waste engine oil, diesel, hydraulic oil, etc.) (water content, impurities, metal content), laying the foundation for pure raw materials. The temperature gradient and vacuum control of the distillation system are optimized to improve the extraction accuracy and yield of diesel fractions and reduce heavy residue. In the refining stage, catalytic reforming technology (selective cracking, hydro-treatment, etc.) is used to remove sulfur and nitrogen impurities and improve stability, ensuring that key product indicators (cetane number, sulfur content, color) are comprehensively superior to high standards such as National VI. The equipment is highly modular and can be flexibly arranged according to customer site conditions, improving deployment efficiency and reducing costs. At the same time, it is equipped with an intelligent control system that integrates online monitoring, feedback, and adjustment to achieve fully automated operation and precise control, improving stability and ease of operation.

System Design

This project focuses on the conversion of waste oil into high-quality diesel. By deploying the company's independently developed waste oil regeneration diesel processing equipment, a full-chain intelligent production system has been built, ranging from waste oil pretreatment to refined diesel production. The core objective of this project is to solve the common problems in the industry, such as "low conversion efficiency due to the complex composition of waste oil," "high energy consumption during production," and "unstable quality of finished diesel." The goal is to achieve efficient, environmentally friendly, and high-value regeneration and reuse of waste oil resources. This project focuses on the conversion of waste oil into high-quality diesel. By deploying the company's independently developed waste oil regeneration diesel processing equipment, a full-chain intelligent production system has been built, ranging from waste oil pretreatment to refined diesel production. The core objective of this project is to solve the common problems in the industry, such as "low conversion efficiency due to the complex composition of waste oil," "high energy consumption during production," and "unstable quality of finished diesel." The goal is to achieve efficient, environmentally friendly, and high-value regeneration and reuse of waste oil resources. This project focuses on the conversion of waste oil into high-quality diesel. By deploying the company's independently developed waste oil regeneration diesel processing equipment, a full-chain intelligent production system has been built, ranging from waste oil pretreatment to refined diesel production. The core objective of this project is to solve the common problems in the industry, such as "low conversion efficiency due to the complex composition of waste oil," "high energy consumption during production," and "unstable quality of finished diesel." The goal is to achieve efficient, environmentally friendly, and high-value regeneration and reuse of waste oil resources. This project focuses on the conversion of waste oil into high-quality diesel. By deploying the company's independently developed waste oil regeneration diesel processing equipment, a full-chain intelligent production system has been built, ranging from waste oil pretreatment to refined diesel production. The core objective of this project is to solve the common problems in the industry, such as "low conversion efficiency due to the complex composition of waste oil," "high energy consumption during production," and "unstable quality of finished diesel." The goal is to achieve efficient, environmentally friendly, and high-value regeneration and reuse of waste oil resources.

1. Intelligent Pretreatment Control

As the first key process in waste oil regeneration, the pretreatment unit is responsible for removing mechanical impurities, water, colloids, and acidic substances from the waste oil. The system uses online sensors to monitor the viscosity, water content, and acid value of the waste oil in real time, intelligently matching the optimal pretreatment process scheme. The high-efficiency filtration component uses a gradient pore size design to intercept impurities of different particle sizes layer by layer; the dehydration module uses vacuum flash evaporation technology to quickly separate free water and emulsified water from the raw materials; the deacidification stage uses precisely metered injection of alkaline additives to achieve neutralization of acidic substances.

2. Molecular Distillation Precise Fractionation

The distillation unit is the core link for extracting diesel fractions from waste oil. It uses the company's unique molecular distillation technology, utilizing the difference in the mean free path of different molecular motions to precisely fractionate waste oil under high vacuum. The system uses an intelligent temperature control module to adjust the temperature of each section of the distillation column in real time, combined with online gas chromatography analysis data, to precisely control the cut point of the diesel fraction, ensuring thorough separation of light and heavy components and significantly improving the yield of diesel fractions. At the same time, the distillation system is equipped with a high-efficiency heat recovery device that can recover the waste heat from the top steam for raw material preheating, greatly reducing energy consumption.

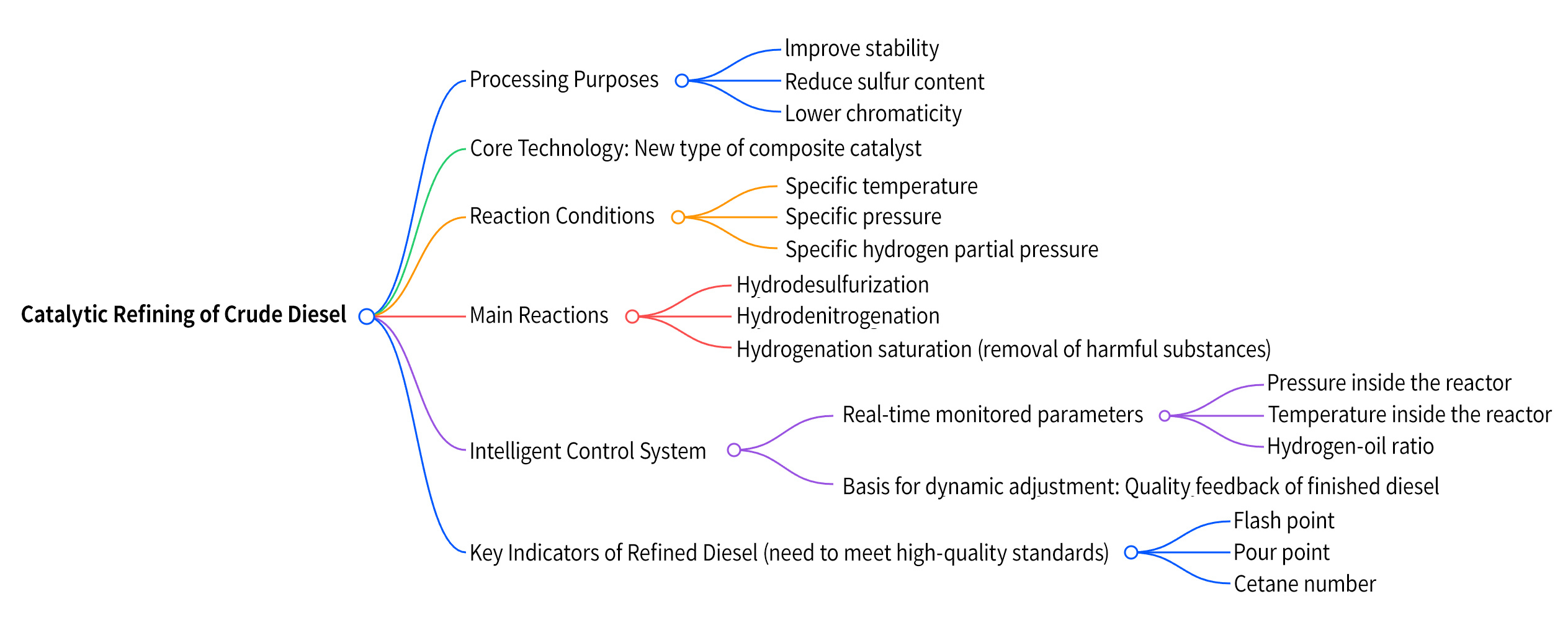

3. Catalytic Refining Quality Improvement

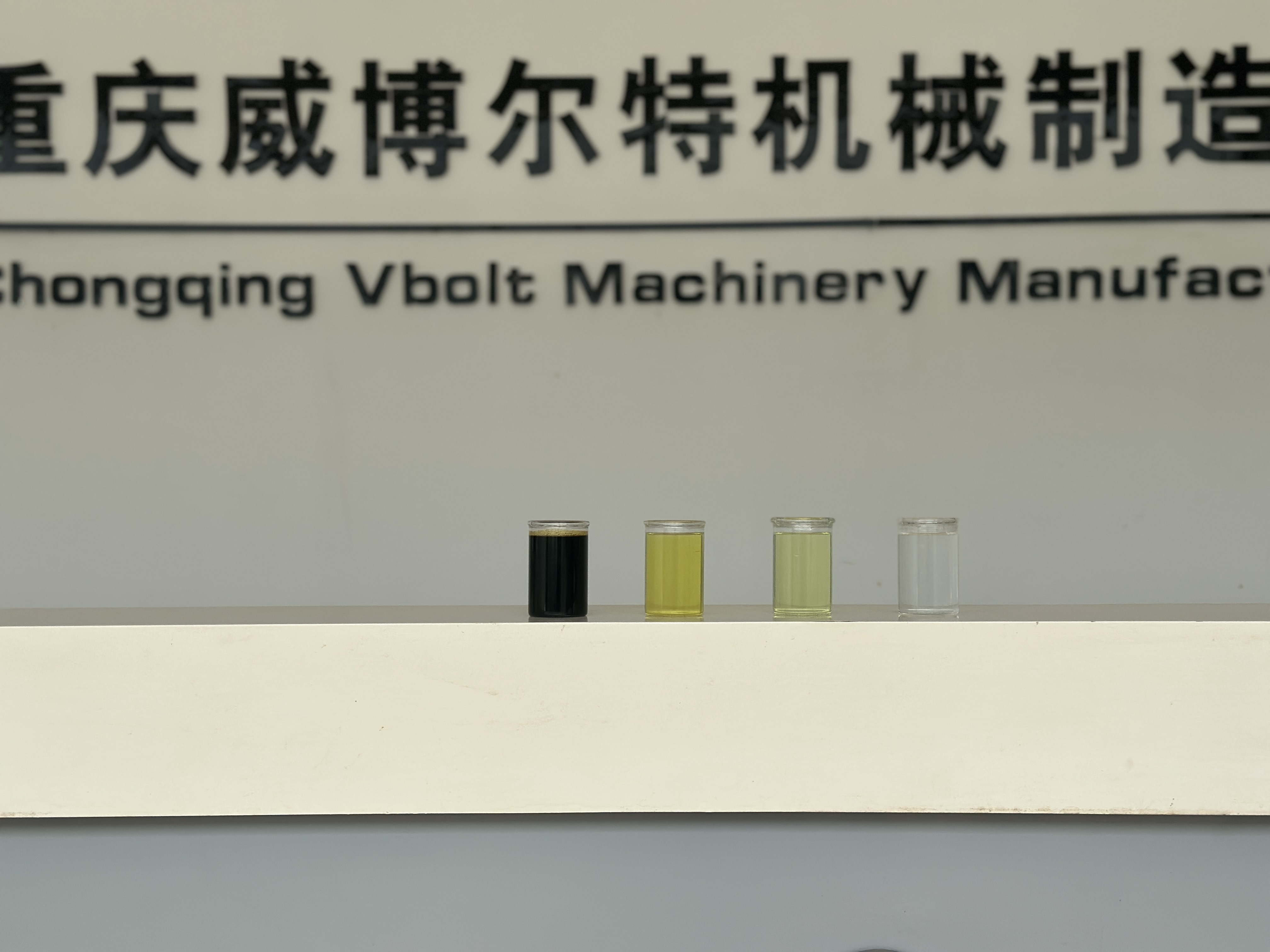

The crude diesel obtained by distillation needs to undergo catalytic refining to improve its stability and reduce sulfur content and color. The system uses a new type of composite catalyst, under specific temperature, pressure, and hydrogen partial pressure conditions, through hydrodesulfurization, hydrodenitrogenation, and hydro-saturation reactions, effectively removing harmful substances from the crude diesel. The intelligent control system monitors the pressure, temperature, and hydrogen-oil ratio in the reactor in real time, dynamically adjusting the reaction conditions based on the quality feedback of the finished diesel to ensure that the refined diesel meets high-quality standards in key indicators such as flash point, pour point, and cetane number.

4. Finished Product Blending and Quality Traceability

The refined diesel enters the finished product blending unit. The system, according to preset product standards, uses precision metering pumps to blend different fractions of diesel in proportion to meet the personalized needs of different customers for diesel quality. At the same time, the system has established a complete quality traceability system. From the entry of waste oil raw materials, the source of each batch of raw materials, pretreatment parameters, distillation data, refining process, and finished product test results are recorded throughout the process, forming a traceable production file. Customers can scan the QR code on the finished product packaging to query the entire production process information of that batch of diesel, enhancing product credibility.

5. Real-time Monitoring of Environmental Protection Indicators

Throughout the production process, the system strictly monitors and treats the emission of waste gas, wastewater, and waste residue. After desulfurization, denitrification, and activated carbon adsorption treatment, the waste gas is monitored in real time by an online monitoring instrument to ensure that the emission standards are met; wastewater is purified through oil-water separation, biological treatment, and other processes for recycling; waste residue is treated using solidification technology for harmless disposal. The intelligent environmental protection monitoring module can upload various environmental protection indicators to the environmental protection supervision platform in real time, realizing transparent management of environmental protection data.

Project Summary

The successful implementation of this project fully demonstrates the company's technical strength and innovation capabilities in waste oil regeneration diesel equipment. Through this intelligent processing system, customers have achieved efficient regeneration and reuse of waste oil resources, not only obtaining high-quality diesel products and creating considerable economic benefits, but also responding to the national call for energy conservation, emission reduction, and a circular economy, achieving good social benefits.

The company is committed to the research and development of waste oil regeneration equipment. Leveraging its deep expertise in core technologies such as pretreatment, distillation, and refining, it can provide customized waste oil regeneration solutions for clients of various scales and needs. In the future, the company will continue to cultivate the waste oil regeneration field, continuously improving the performance and intelligence level of its equipment, and promoting the industry towards a greener, more efficient, and more sustainable direction, contributing to global resource recycling.

Latest News

2024-11-06

Why does waste slag coke?

Used lubricating oil contains a variety of impurities, and due to the presence of detergent dispersants (a commonly used additive)

2024-11-06

What is the working principle of a vacuum oil filter?

Vacuum oil filter is suitable for degassing, impurity removal, water filtration and purification, and waste oil regeneration of industrial oils such as transformer oil, turbine oil, lubricating oil, and hydraulic oil.

2024-11-06

Application of fiber ball filter in oilfield wastewater treatment

In oilfield produced water treatment, there is a problem of substandard water quality. There are many factors contributing to this situation, the most important of which is the filter problem. Filtration is the last resort for removing suspended solids and oil.

2024-11-06

How to use a backwashing filter? Remember these points, and operation will not be a worry

Backwashing filters are now one of the important environmental protection equipment in wastewater treatment, and are well-known for their efficient wastewater treatment capabilities.