Summary of the Scheme

Design goals

Technical principle

Final effect

- PRODUCT

Summary of the Scheme

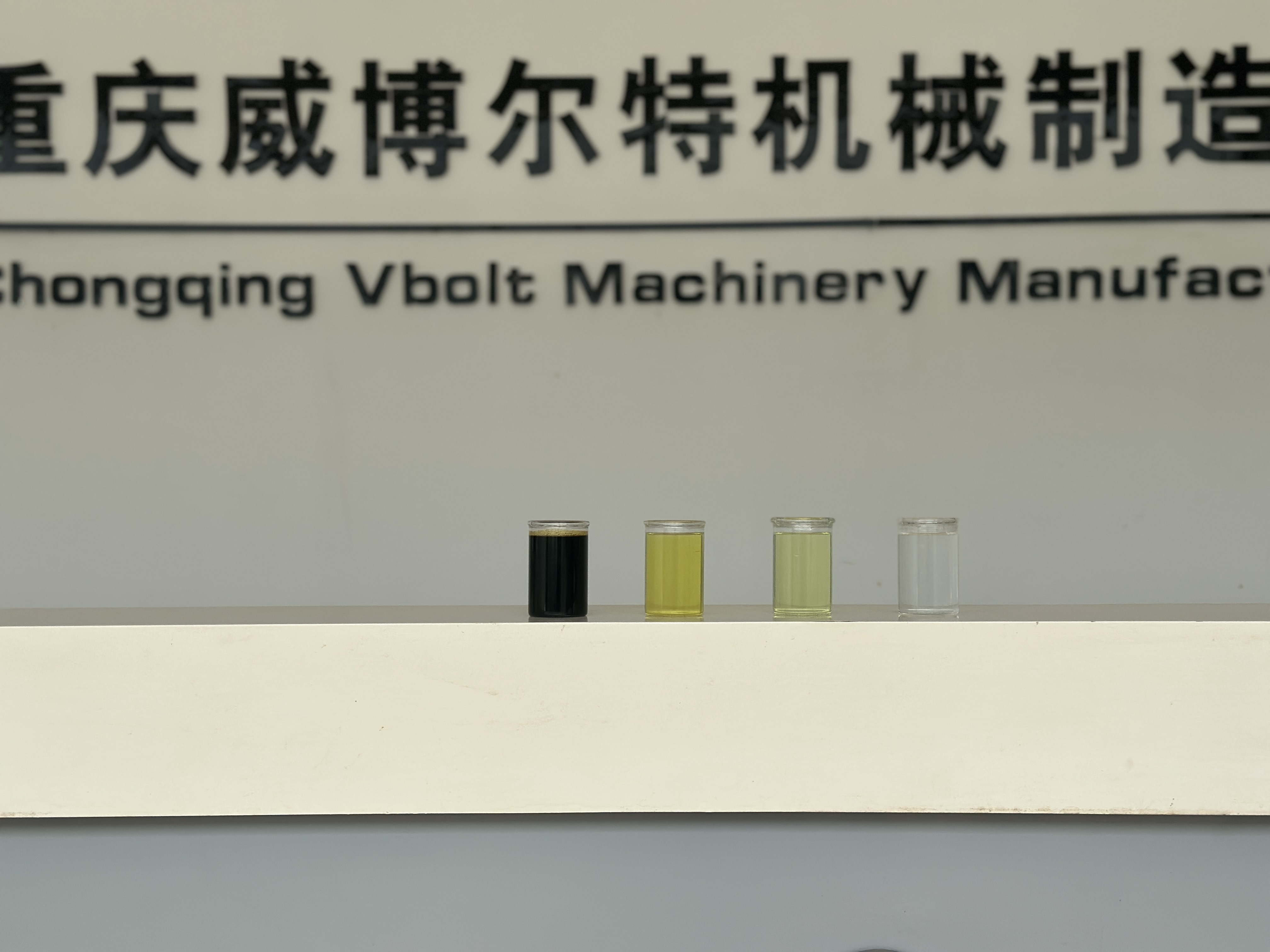

In Iraq, waste engine oil, once deemed a "black curse," is being transformed in a new factory. The VBOLT waste oil regeneration system, developed by Chongqing Vbolt Machinery Manufacturing Co., Ltd., converts tons of black waste oil into clear diesel fuel daily. This facility has eliminated the hazardous waste accumulation from local enterprises and achieved the highest profit margins in the region, contributing to a new chapter in the circular economy.

- PRODUCT

Design goals

1. Technological Breakthrough Under Extreme Conditions

Faced with continuous extreme weather disturbances, the VBOLT engineering team innovatively developed a "dual-mode temperature control system", using intelligent variable frequency technology

to control reaction temperature fluctuations within a controllable range; a multilayer composite filtration device can intercept 0.1-micron metal debris, ensuring that in Iraq

under harsh conditions, it still maintains a continuous operation efficiency of 98.7%.

2. Molecular Breakthrough in Regeneration Technology

Using the unique technology of "micro-pressure catalysis", precise reorganization of hydrocarbon chains is achieved in a vacuum environment. Compared with traditional processes, the diesel conversion rate

has increased to around 90%, and the sulfur content has been tested to meet standards. The clean diesel produced can be directly adapted to local generator sets and engineering machinery.

- PRODUCT

Technical principle

Our waste oil to biodiesel equipment utilizes advanced regeneration technology, enabling stable operation under high temperature and high-pressure conditions to ensure the efficient and environmentally friendly regeneration of waste oil into diesel fuel. Stable equipment operation is fundamental to producing high-quality diesel, a goal our company consistently pursues. Our equipment's performance has been proven in Iraq, where it has successfully withstood rigorous testing.

Our waste oil to biodiesel equipment utilizes advanced regeneration technology, enabling stable operation under high temperature and high-pressure conditions to ensure the efficient and environmentally friendly regeneration of waste oil into diesel fuel. Stable equipment operation is fundamental to producing high-quality diesel, a goal our company consistently pursues. Our equipment's performance has been proven in Iraq, where it has successfully withstood rigorous testing.

- PRODUCT

Final effect

After the project was implemented and put into operation, this equipment, with a daily processing capacity of nearly 100 tons, has created and demonstrated multiple values:

1. Ecological dimension: The daily reduction in CO₂ emissions is equivalent to creating dozens of hectares of oasis in desert areas.

2. Economic dimension: The customer has achieved a diesel self-sufficiency rate of around 90%, saving millions of dollars in annual energy procurement costs.

3. Social dimension: Created dozens of technical positions and cultivated the first batch of waste oil regeneration engineers in Iraq.

4. Modular design: The system is decomposed into 23 standard modules to achieve rapid production.

5. Adaptive transformation: Research and development of special wind-cooled protective covers allow the equipment to maintain an attendance rate of approximately 94% even in extreme weather.

6. Cyclical training system: Through VR simulation system + on-site operation, the full-post skill migration is completed as scheduled.

This dual output of "hard technology + soft power" makes VBOLT manufacturing more than just simple equipment export, but a system transplant of sustainable productivity. As the chief engineer of VBOLT said at the project acceptance: "What we deliver is not a cold steel behemoth, but a whole breathing circular economy ecosystem."

- VBOLT

Related product recommendations

Waste oil regeneration diesel equipment

Base oil solvent extraction equipment

Lubricating oil blending equipment

Used oil re-refining base oil equipment

- I WANT TO CONSULT

I want to consult

During the process of browsing our products, is there anything that you are particularly satisfied with or that needs to be improved? Your consultation or suggestions will directly help us improve product and service quality and bring you a more intimate experience.

* Please fill in the above fields (* indicates required fields), and we will reply to your feedback as soon as possible.

FAQ

Please refer to the following instructions for your questions